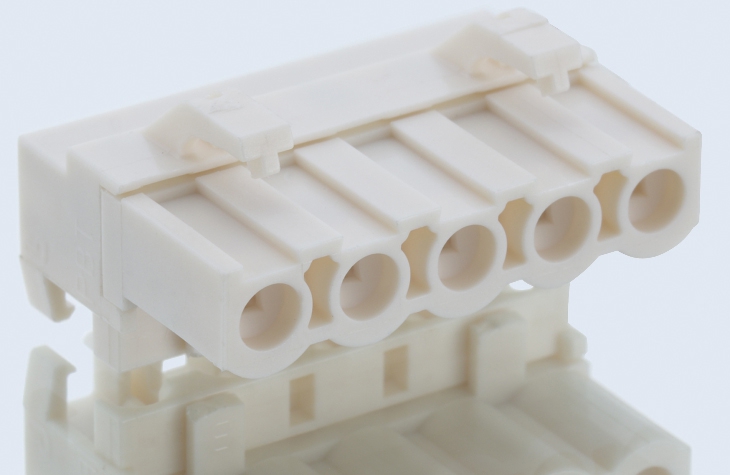

Pluggable Terminal Block in IDT – Unique, Yet Universal

Schalksmühle, 15.07.2014. Quite popular is the use of all kinds of pin headers. For an easy and safe connection of peripheral components, such as pumps or external sensors, often terminal blocks will mate on these pin headers, which are predominantly based on screw clamps. These pluggable terminal blocks allow an easy wiring and convenient connection of the peripheral devices.

A lot different is the production of major devices which are assembled on an industrial scale as any potential for economization must be squeezed out. And no installer will have to take action in the field afterwards. Lumberg now launches its 67-series pluggable terminal block, pitch 5.08 (.200″) in IDT. When it comes to efficient processing of pre-assembled terminal blocks, insulation displacement technology (IDT) is head and shoulders to screw clamps. Especially with high volumes and automated production its advantages snowball. Also typical for IDT harnessing: a significant advance in quality, as testing procedures are integrated in-line. And all conductors are prevented from detaching later on, which is occuring occasionally with manually wired screw clamps.

For signal and load currents of up to 6 A the pluggable terminal block 6770 matches many common pin headers available in the market at the same pitch of 5.08 mm. With a 90° or 180° cable departure to the plugging direction, with locking and keying option as well as a test hole the 2 to 7-poles terminal block can be placed consecutively on pin headers without loss of pitch. Being just as reliable, but in semi-automated processing a much faster alternative, the terminal block 6770 in IDT is the ideal choice for indirect mating on many manufacturers’ pin headers. With tin-plated contacts and rated currents of up to 6 A at Tamb 70 °C within a temperature range of -25 to +100 °C conductors with a 0.5‒0.75 mm² section can be connected; when using an alternative insulation displacement terminal they can be used for diameters of between even 0.2 and 0.38 mm². The maximum insulation diameter is 2.5 mm.

Total no. of characters incl. blanks: 2.112

Media Contact:

Lumberg Holding GmbH & Co. KG

Im Gewerbepark 2

58579 Schalksmühle

Germany

Kai Rotthaus

T +49 2355 83-1275

Press Release as PDF Printable Photo