Heating Technology:

Direct Connector-to-PCB Mating Moving Forward

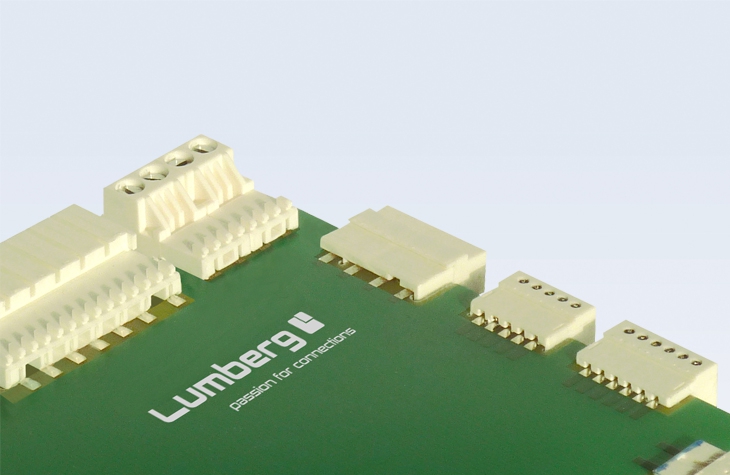

Schalksmühle, 20.02.2015. Direct mating for PCBs has always been closely tied to heater equipment and for some years now, it has also been extensively associated with the automotive industry. Precision installation spaces are just one of the reasons to directly mate the PCBs’ edge. Potential savings equally play a role when it comes to the high-volume use of connectors that forgo the pin or tab header.

“Installation space is becoming increasingly defined in heating technology”, according to the latest guiding principle as seen for example, in the control units of these highly complex installations. Christian Forner, head of sales of Lumberg Connect, hears about this more and more often from manufacturers operating within heating technology just before the industry’s ISH fair in Frankfurt is about to kick off. “We supply all the renowned manufacturers around the world and are in close contact with their development departments and product designers. Especially wall-mounted gas-fired boilers fitted in kitchens, where more often than not the pump, burner, heat exchanger and electronics have to be integrated behind a single door, demonstrate that miniaturisation has progressed considerably with leading manufacturers opting for direct mating. Ten years ago, the proportion of classic mass-volume devices using indirect connectors compared to those using direct connectors was around 70:30 – today it has at least levelled at 50:50.”

When it comes to larger, higher quality non-gas-fired wall-mounted devices such as floor-standing boilers, heat pumps, hybrid systems and especially, pellet units, Forner can already establish a clear trend in favor of direct connectors even if in these cases, installation space is not the decisive argument.

But even heating technology distinguishes between two trends for direct connectors: whereas in the meantime the proportion between RAST 5 connectors and slimmer-fitting RAST 2.5 connectors is even, substituting the RAST 5 family with the RAST 2.5 Power is clearly taking over. With a distinctively higher current rating of 6 Amps at TU 70 °C and a 400 Volt rated current, these connectors are clearly closer to a RAST 5 connector – like the common 3636 RAST 5 IDT connector with 6 Amps at TU 70 °C and a rated voltage of 250 Volt – compared with a 3521 as a highly-common RAST 2.5 connector with 4 Amps at TU 60 °C and a rated voltage of 32 Volt.

But Lumberg listens to its customers’ wishes even for its broad range of RAST 5 connectors. Although the layout of RAST 5 direct IDT connectors has been known for decades, with the 3612, the 3613 and the all-new 3614, Lumberg debuted a 2- to 6-pin direct connector with a 5 mm pitch, 6 Amps at TU 70 °C and a rated voltage of 250 Volt in screw clamp technology as a new addition to its program.

Total no. of characters incl. blanks: 2.864

Media Contact:

Lumberg Holding GmbH & Co. KG

Im Gewerbepark 2

58579 Schalksmühle

Germany

Kai Rotthaus

T +49 2355 83-1275

Press Release as PDF Printable Photo